7 Ultimate Ways To Create Closed Loop Now

Introduction to Closed Loop Systems

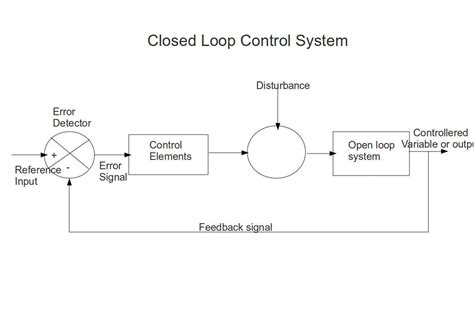

In today’s fast-paced, technology-driven world, closed loop systems have become increasingly popular due to their ability to provide real-time feedback and improve overall efficiency. A closed loop system is a type of control system where the output of the system is continuously monitored and compared to the desired output, allowing for adjustments to be made as needed. This creates a continuous loop of feedback and adjustment, resulting in a more accurate and efficient system. In this article, we will explore the 7 ultimate ways to create a closed loop system.

Understanding the Benefits of Closed Loop Systems

Before we dive into the ways to create a closed loop system, it’s essential to understand the benefits of such a system. Some of the key benefits include: * Improved accuracy: Closed loop systems provide real-time feedback, allowing for adjustments to be made as needed, resulting in a more accurate output. * Increased efficiency: By continuously monitoring and adjusting the output, closed loop systems can optimize performance and reduce waste. * Enhanced reliability: Closed loop systems can detect and respond to errors or changes in the system, reducing the risk of downtime or malfunction.

7 Ultimate Ways to Create a Closed Loop System

Now that we’ve explored the benefits of closed loop systems, let’s take a look at the 7 ultimate ways to create one: * 1. Define the System’s Objective: The first step in creating a closed loop system is to define the system’s objective. This will help determine the desired output and the metrics used to measure performance. * 2. Choose the Right Sensors: Sensors are used to monitor the output of the system and provide feedback. Choosing the right sensors is crucial to ensure accurate and reliable data. * 3. Select a Control Method: There are various control methods to choose from, including PID (Proportional-Integral-Derivative) control, fuzzy logic control, and model predictive control. The choice of control method will depend on the specific application and system requirements. * 4. Implement Feedback Mechanisms: Feedback mechanisms are used to compare the actual output to the desired output and make adjustments as needed. This can include feedback from sensors, as well as feedback from users or operators. * 5. Use Data Analytics: Data analytics can be used to analyze the data from the sensors and feedback mechanisms, providing insights into system performance and identifying areas for improvement. * 6. Implement Continuous Monitoring: Continuous monitoring is essential to ensure that the system is operating within the desired parameters. This can include monitoring system performance, as well as monitoring for errors or changes in the system. * 7. Optimize and Refine the System: Finally, it’s essential to continuously optimize and refine the system to ensure that it is operating at peak performance. This can include adjusting control parameters, updating algorithms, and implementing new technologies or techniques.💡 Note: Creating a closed loop system requires careful planning and attention to detail. It's essential to consider the specific application and system requirements when designing and implementing a closed loop system.

Real-World Applications of Closed Loop Systems

Closed loop systems have a wide range of real-world applications, including: * Process control: Closed loop systems are used in process control applications, such as temperature control, pressure control, and flow control. * Robotics and automation: Closed loop systems are used in robotics and automation applications, such as robotic arms, autonomous vehicles, and industrial automation. * Aerospace and defense: Closed loop systems are used in aerospace and defense applications, such as guidance and navigation systems, and flight control systems.

| Application | Description |

|---|---|

| Process control | Closed loop systems are used to control temperature, pressure, and flow in industrial processes. |

| Robotics and automation | Closed loop systems are used to control robotic arms, autonomous vehicles, and industrial automation systems. |

| Aerospace and defense | Closed loop systems are used in guidance and navigation systems, and flight control systems. |

In summary, closed loop systems offer a range of benefits, including improved accuracy, increased efficiency, and enhanced reliability. By following the 7 ultimate ways to create a closed loop system, and considering the specific application and system requirements, you can create a highly effective and efficient closed loop system. The key points to take away are the importance of defining the system’s objective, choosing the right sensors, selecting a control method, implementing feedback mechanisms, using data analytics, implementing continuous monitoring, and optimizing and refining the system. With the right approach and technologies, closed loop systems can be used to improve performance and efficiency in a wide range of applications.

What is a closed loop system?

+A closed loop system is a type of control system where the output of the system is continuously monitored and compared to the desired output, allowing for adjustments to be made as needed.

What are the benefits of a closed loop system?

+The benefits of a closed loop system include improved accuracy, increased efficiency, and enhanced reliability.

How do I create a closed loop system?

+To create a closed loop system, follow the 7 ultimate ways outlined in this article, including defining the system’s objective, choosing the right sensors, selecting a control method, implementing feedback mechanisms, using data analytics, implementing continuous monitoring, and optimizing and refining the system.