Military

10 Pro Ways To Create Under Armour Boots Today

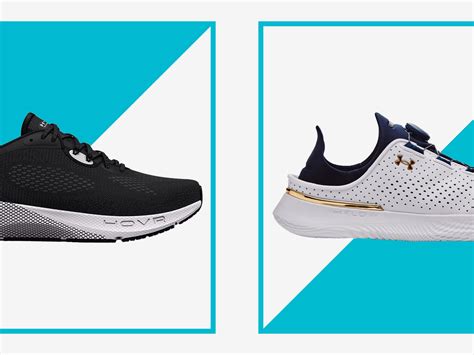

Introduction to Under Armour Boots Creation

Creating Under Armour boots requires a combination of innovation, quality materials, and a thorough understanding of footwear design. With the rise of athletic and outdoor activities, the demand for comfortable, durable, and high-performance boots has increased significantly. In this article, we will explore the steps and techniques involved in creating Under Armour boots, highlighting the key considerations and best practices for manufacturers and designers.

Understanding the Requirements

Before diving into the creation process, it’s essential to understand the requirements and specifications of Under Armour boots. These boots are designed for various activities, including hiking, running, and training, and must provide a combination of comfort, support, and traction. The key features of Under Armour boots include: * Waterproofing: To keep feet dry and comfortable in wet conditions * Breathability: To allow for airflow and moisture wicking * Cushioning: To provide shock absorption and comfort * Traction: To offer grip and stability on various surfaces

Designing the Boot

The design process involves creating a prototype that meets the requirements and specifications of Under Armour boots. This includes: * Sketching: Creating initial sketches and concepts * Computer-aided design (CAD): Using software to create a digital model * Prototyping: Creating a physical prototype for testing and refinement The design should take into account the intended use, target audience, and brand identity.

Materials and Manufacturing

The selection of materials and manufacturing process plays a crucial role in the creation of Under Armour boots. Common materials used include: * Leather: For durability and water resistance * Synthetic materials: For lightweight and breathable options * Rubber: For outsoles and traction The manufacturing process involves: * Cutting: Cutting the materials to the required shape and size * Stitching: Assembling the components using stitching or bonding * Molding: Shaping the outsole and other components using molding techniques

Quality Control and Testing

To ensure that the Under Armour boots meet the required standards, quality control and testing are essential. This includes: * Inspecting: Visually inspecting the boots for defects or imperfections * Testing: Conducting performance tests, such as waterproofing and traction tests * Feedback: Gathering feedback from wearers and making adjustments accordingly

Customization and Personalization

Under Armour boots can be customized and personalized to meet individual preferences and needs. This includes: * Color options: Offering a range of colors and color combinations * Size options: Providing a range of sizes to fit different foot shapes and sizes * Accessories: Offering additional accessories, such as laces and insoles🔍 Note: It's essential to consider the target audience and their specific needs when customizing and personalizing Under Armour boots.

Marketing and Distribution

The final step in creating Under Armour boots is marketing and distribution. This includes: * Branding: Creating a strong brand identity and marketing campaign * Distribution: Establishing relationships with retailers and distributors * Online presence: Creating an online presence, including e-commerce and social media

Conclusion and Final Thoughts

Creating Under Armour boots requires a combination of innovation, quality materials, and a thorough understanding of footwear design. By following the steps and techniques outlined in this article, manufacturers and designers can create high-performance boots that meet the demands of athletes and outdoor enthusiasts. Whether you’re a seasoned manufacturer or an emerging designer, understanding the requirements, designing the boot, selecting materials, and testing the final product are all crucial steps in creating Under Armour boots that exceed expectations.

What are the key features of Under Armour boots?

+The key features of Under Armour boots include waterproofing, breathability, cushioning, and traction.

What materials are commonly used in Under Armour boots?

+Common materials used in Under Armour boots include leather, synthetic materials, and rubber.

How can I customize and personalize Under Armour boots?

+Under Armour boots can be customized and personalized by offering color options, size options, and accessories such as laces and insoles.